01.

Smart Phone

- - AP plasma (M electrode) is applied to the foldable phone assembly process

- - AP plasma (M electrode) is applied to the touch panel lamination/coating pretreatment process

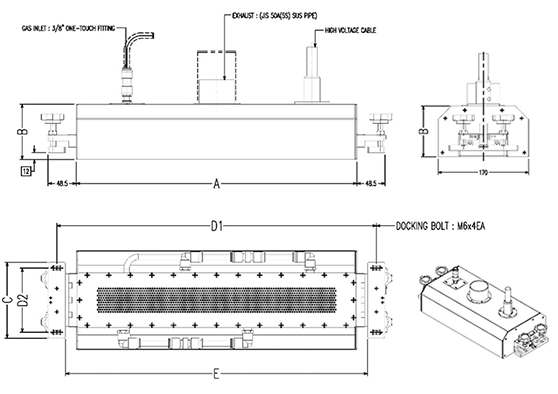

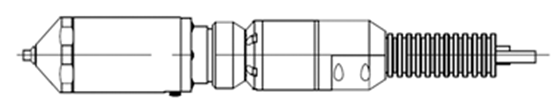

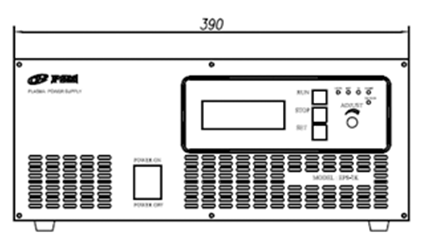

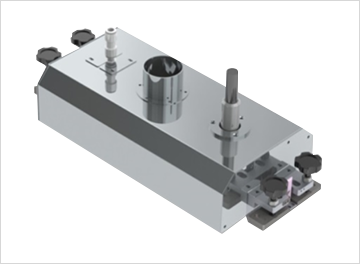

APM Electrode

- 1. It has a very good cleaning effect / surface modification characteristics (2-3 times higher cleaning effect than the existing atmospheric pressure module)

- 2. Gap between sample and electrode is larger than the existing electrode (~5 mm Max.)

- 3. Stable / safe use of electrode is possible through the low operating voltage (~8kV) and low power (0.5~1.5kW).

- 4. It is applicable as roll-to-roll equipment to CPI/UTG substrate surface cleaning and coating pretreatment processes